Automatic MDS

MDS excellence

Which dispensing robot best fits your needs?

With the automatic or automated MDS you will prepare multi-dose MDS in pouch or blister format with maximum efficiency and safety. Discover the automatic MDS that best suits your pharmacy and take another step towards a service-based pharmacy.

What difference is there between automatic MDS dispensing robots?

Larger size, enhanced efficiency

The main difference is the number of high-rotation medications that can be managed in the canisters. The larger the dispensing robot, the greater the number of canisters, meaning less handling and more efficiency.

A canister is a hopper calibrated to a specific medication by shape and size. It is identified by an RFID code the dispensing robot recognizes regardless of location.

How many patients are needed to make it worth buying an automatic dispenser for a pharmacy?

Although we have more than 11 models of automated MDS robots, automation makes more sense for a larger volume of patients. The bigger the MDS robot, the more medicine it can manage automatically and the efficiency of the multi-dose MDS system increases proportionally. For less than 80-100 patients per pharmacy, we generally recommend the Semiautomatic MDS. However, we analyse each pharmacy individually to recommend the MDS robot that best adapts to its circumstances.

How are low-rotation medications managed?

MDS dispensing robots enable the onboarding of autocanisters (universal hoppers) that make it possible to automatically add a specific or occasional medication according to your needs, even split dose tablets.

They also have a multi-patient STS tray system for manually adding low-rotation medication or medications not assigned to a canister.

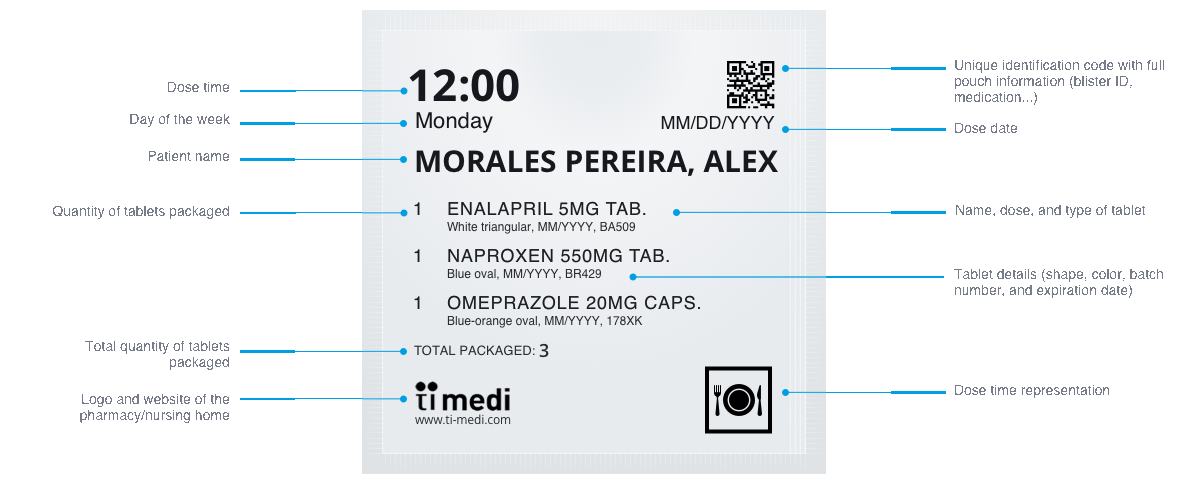

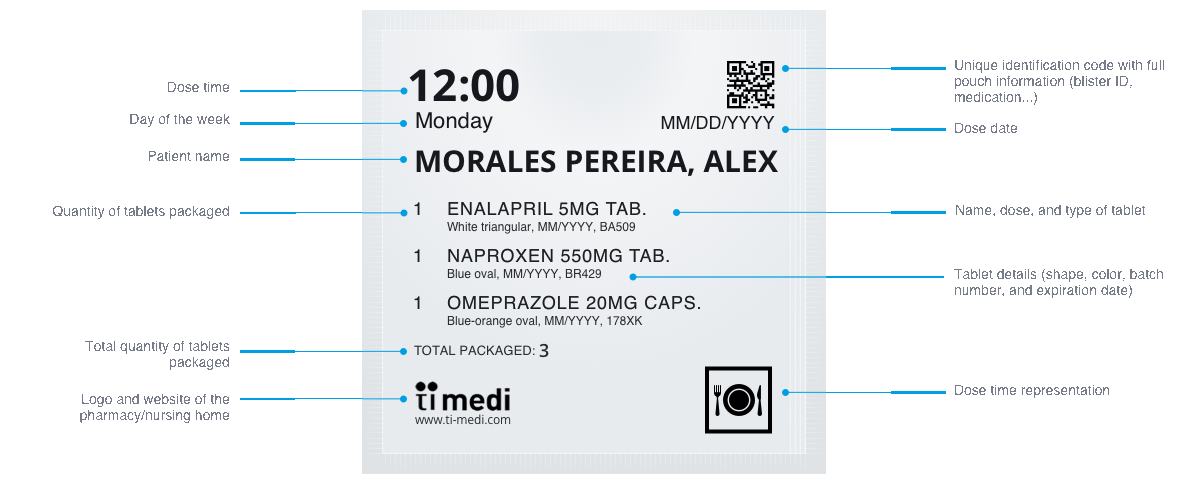

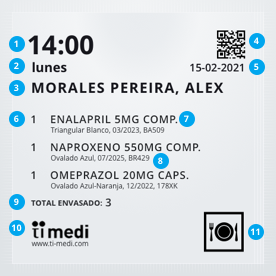

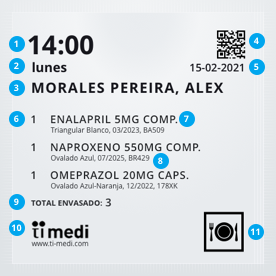

Fully customizable pouch design

All the information printed on the pouch is customizable and can be identified with the Data Matrix code to guarantee traceability.

- Dose time

- Day of the week

- Patient name

- Unique identification code with full pouch information (blister ID, medication…)

- Dose date

- Quantity of tablets packaged

- Name, dose, and type of tablet

- Tablet details (shape, color, batch number, and expiration date)

- Total quantity of tablets packaged

- Logo and website of the pharmacy/nursing home

- Dose time representation

Variable pouch size (optional)

The pouch size can be adjusted according to the number of tablets included in it, minimizing use of consumables.

Easy replacement of consumables

The removable consumable formats facilitate replacement, optimizing MDS preparation process continuity.

GMP-compliant

Fast and easy cleaning

Automatic blistering machines allows for hands-free medication liberation, preventing cross-contamination and facilitating cleaning.

Simple, safe, and efficient

Intuitive software under constant development

Ti-Dose pro is the foundation for MDS excellence

- Integrated with pharmacy management programs

- Patient and dose management

- Pharmacy validation

- Complete traceability

- Report generation

- Stock control

Data sheets

Enter your email and we will send you the requested data sheets